Measuring Technology of Machining Accuracy of Machine Parts

In the process of mechanical production and processing, strict control of processing accuracy can ensure the production quality of parts and help promote the development of modern manufacturing. In production, technicians often control the machining quality of machine parts by measuring the machining accuracy of the machine parts.

In the actual measurement work, in order to ensure the processing accuracy, technicians need to correctly understand the following measurement techniques, clarify their measurement accuracy and error problems in use, so as to effectively improve the accuracy of the precision measurement and improve the production quality of parts.

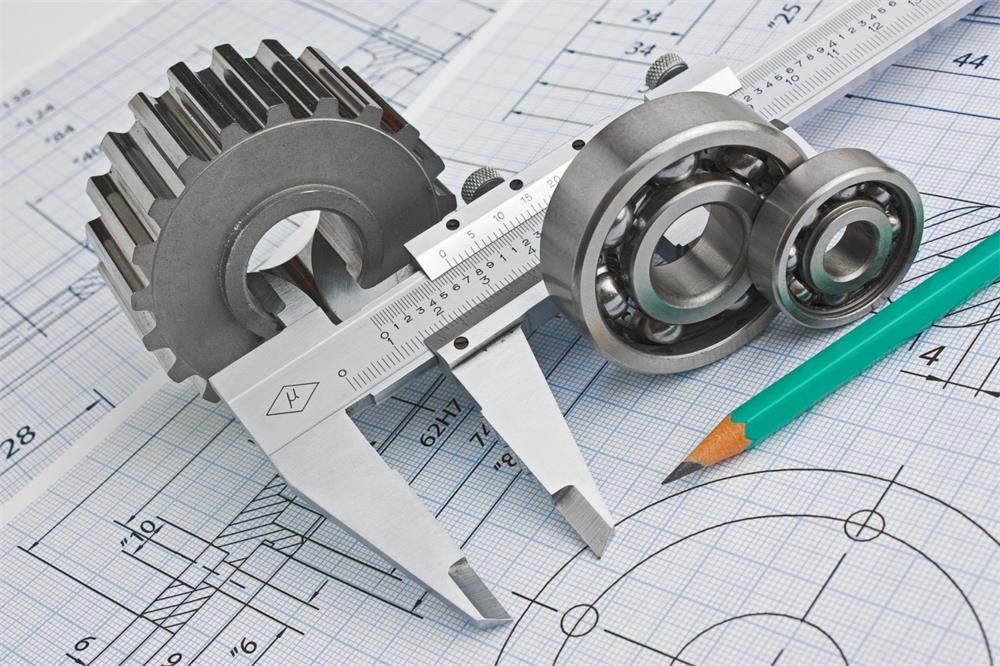

Steel ruler and caliper measurement

The steel ruler is used to measure the length data of the part in the traditional machining accuracy measurement, and its measurement accuracy is millimeter level, so pay attention to the measurement range in actual use. In order to improve the measurement accuracy, technicians generally use steel rulers and calipers together.

The calipers are simple measurement tools. The inner calipers can measure the inner diameter and groove size parameters of some circular parts, and the outer calipers can measure the outer diameter of the parts. Data such as diameter and plane length are measured, and the caliper needs to be matched with a steel ruler to read the data.

In the actual measurement, these two measurement methods generally do not measure some parts with higher accuracy. Due to the lack of understanding of data reading and measurement rules by some measurement personnel, large measurement errors may occur with these two measurement tools, and more attention should be paid to the measurement work.

Vernier caliper and micrometer measurement

In the measurement of machining accuracy of mechanical parts, vernier calipers and micrometers are the two most commonly used measuring equipment. The vernier caliper is convenient to use, and its measurement accuracy is higher than the traditional steel ruler measurement method. The main measurement objects of vernier calipers are geometric parameters such as the outer diameter, inner diameter, and length of the part.

Compared with vernier calipers, the measurement accuracy of micrometers is higher, and the measurement is more sensitive. Generally, some parts that require higher measurement accuracy are measured.

Both of these measurement methods require manual operation. In the current large-scale production, manual accuracy measurement seriously affects production efficiency. At the same time, manual measurement is often difficult to avoid errors. In order to reduce errors, measurement personnel needs to perform multiple operations. Measurement has a great impact on production efficiency, and it has been difficult to adapt to the needs of modern mechanical production.

In the measurement process of the vernier caliper, the analysis of the indication error should be carried out according to the national standard for the error. In order to ensure accuracy during the measurement, a third-level or fifth-level measurement block should be used for the verification process.

In the course of the experiment, multiple verification points are generally selected for measurement in order to measure efficiency. In the selection of verification points, the experimenter can determine the verification points according to the actual measurement range of the vernier caliper.

Dial indicator measurement

In the measurement of machining accuracy of mechanical parts, the use of a dial indicator is quite special. The measurement data is relative data. Generally, the error data of mechanical parts is measured. Common measurement objects include the flatness, roundness, and beating frequency of the parts. It can directly reflect the machining accuracy of parts. The scale of the dial indicator is divided into 100 equal divisions. The pointer advances a small division to indicate that the measurement data moves by one millimeter.

In actual use, the technician needs to record the data of the small pointer and the large pointer separately, and add the two Obtain the final measurement data of the part.

Several traditional precision measurement technologies rely on manpower to complete, the measurement efficiency is low, the data analysis is difficult, and it is difficult to meet the production needs of the modern machining industry.

Therefore, under the background of modern science, technicians should combine modern information technology to innovate the measurement methods of parts accuracy and improve the accuracy of measurement. If you want to know more about the content after reading the above, you can contact us for a comprehensive solution.

As an experienced parts supplier, ZHONGKEN is specialized in the production of various mechanical parts, mold connectors, castings, and sheet metal parts. We are equipped with a professional quality inspection system and a comprehensive quality management team, which can control the quality of our products in an all-round way. Our high-quality parts are sold all over the world and have received praise and trust from many customers. If you are interested in our products, please contact us immediately!