WEDM&EDM Service

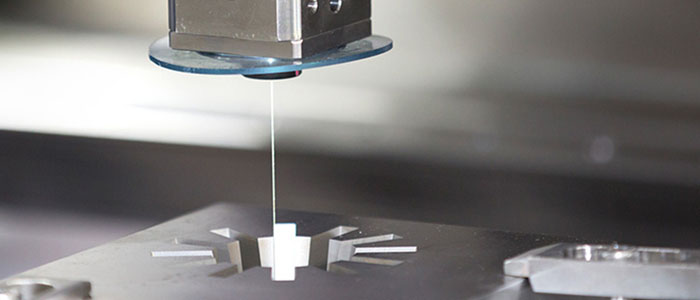

Electrical Discharge Machining (EDM) is an advanced machining process that relies on the precise application of electrical sparks to produce a desired part shape or finish. Wire EDM (WEDM) is a variation of the EDM machining method that is often used for cutting plates or forming ties, tools or punches from harder metals that are typically not conducive to standard machining processes.

Wire EDM is much more accurate than traditional machining, it uses a strand of wire as a cutting tool creates a linear line, and therefore Wire EDM services are commonly used to cut all of the way through the material. Wire EDM is best suited for projects that have intricate tolerances, material stress limitations, and/or surface finish requirements.

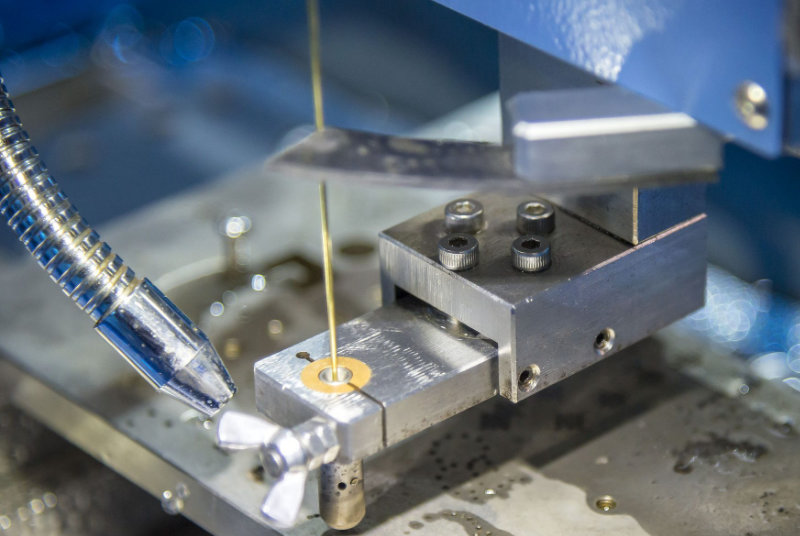

Micro Diameter EDM Holes With High Precision And Superior Edge Quality

Another area where SANS specializes is EDM blind and through hole drilling, we can provide micro hole and small hole EDM drilling services on complex parts.

Our dedicated CNC-operated EDM small hole drilling machine can produce holes as small as 0.2mm in some of the hardest conductive materials. When popping or drilling holes in fast or small holes, size and weight are rarely limited. By using the most advanced EDM generator technology and electrode materials, high-precision hole size, excellent hole edge quality and surface finish can be achieved, and the overall precision and consistency of parts can be improved.

Capacity

Standard Wire EDM:

Size: 600*350*200mmTolerance:+/-0.05mmPrecision Wire EDM

Size:400*250*250mmTolerance:+/-0.002mmSmall Hole Diameter:0.2mm

Material

Application

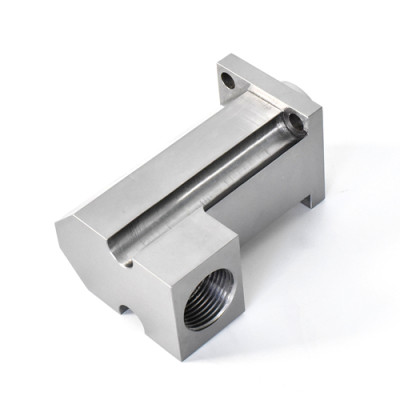

Our EDM & Wire EDM Parts

- Dalian Zhongken Machiney to Exhibit at M-Tech Osaka 2025We are pleased to announce that from October 1 to October 3, 2025, we will participate in the 28thM-Tech Osaka. Our booth is located at Hall 6, B Zone, Booth 54-6. Looking forward to meeting you in Osaka!

- Aluminum CNC Machined Parts: Why Do You Need Them?Aluminum is one of the most successful commercial metals in human history. The material has been used to make durable and lightweight parts in industries such as aerospace, military and defense, and other industries. This article discusses some interesting things about aluminum CNC machined parts.

- *Name

- *Mobile Phone

- *Title

- *Content