ZK CNC Milling Machining Service

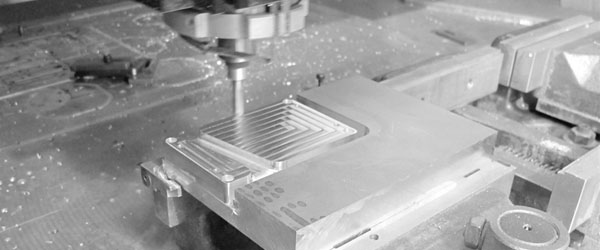

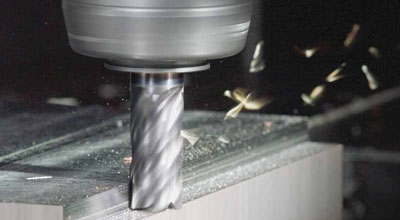

CNC milling machining follow very detailed translation instructions for CAD or CAM models. CNC machine tools can have up to a five-axis control system to mill workpieces from multiple simultaneous angles using different tools. This helps to manufacture complex and precise milled parts faster than ever.

CNC milling is one of our key specialties. We provide horizontal and vertical milling service to meet any production and design needs. It supports 3-axis, 4-axis, 5-axis milling and right-angle milling functions, which can meet your requirements from simple straight lines to complex geometric shapes, and at the same time meet the production requirements of highly accurate and high-quality parts.

Our CNC milling process can produce customized prototypes and final production parts within one day at the fastest. Provide quality inspection reports, material certifications, and other finishing options such as anodizing and chromate plating etc..

Process Type

Capacity

Material and Surface Finishing For CNC Machining

Main Materials

| Aluminum | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. |

| Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416, etc. |

| Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc. |

| Copper | C11000, C12000, C12200, C10100, etc. |

| Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Plastic | POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc |

Surface Treatment

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating Etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated |

| Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing,Power Coated, Nickel Plated Etc. |

| Plastic | Plating gold (ABS), Painting, Brushing (Acylic), aser engraving |

Quality Control

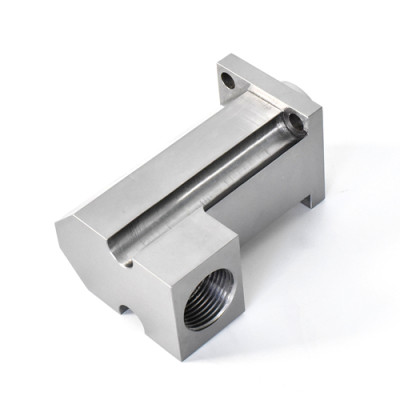

Our CNC Miiling Parts

- Dalian Zhongken Machiney to Exhibit at M-Tech Osaka 2025We are pleased to announce that from October 1 to October 3, 2025, we will participate in the 28thM-Tech Osaka. Our booth is located at Hall 6, B Zone, Booth 54-6. Looking forward to meeting you in Osaka!

- Aluminum CNC Machined Parts: Why Do You Need Them?Aluminum is one of the most successful commercial metals in human history. The material has been used to make durable and lightweight parts in industries such as aerospace, military and defense, and other industries. This article discusses some interesting things about aluminum CNC machined parts.

- *Name

- *Mobile Phone

- *Title

- *Content